Strong, fast-drying, cheap, durable. When polyester first came onto the market about 70 years ago, it was acclaimed as a miracle fabric. There would be no need anymore to spend hours washing clothes and giving garments special treatment.

Read this story in one minute

In 1951, the New York Times described polyester as a durable, luxurious fabric that paid for itself and lasted much longer than other clothing.

The new fibre’s popularity was reflected in the figures. Within 20 years, polyester had become one of the most widely used materials in the clothing industry. In 2007, the younger fabric had eclipsed cotton – for centuries, one of the most widely produced textile fibres – as the most-consumed fabric. Polyester has been number one for 10 years.

That dominance is reflected on the racks of clothing stores. In pullovers, T-shirts, trousers, blouses and jackets, polyester is listed on many of the clothing labels.

Polyester has never offered the illusion of being clean. The fabric is made from petroleum, and is energy-intensive to produce. Even so, for many years, it seemed a promising alternative to farming cotton, which requires large amounts of water and farm land, often consuming harmful pesticides. Cotton is harder to recycle, too.

So on several important measures, polyester didn’t seem all that bad. Until recently, a conspicuous disadvantage of this "miracle fibre" remained invisible.

Synthetic fibres in the sea

The early signs were discovered in 2004. A team of researchers led by Richard Thompson, Britain’s leading marine biologist, began studying samples of sea water at 20 locations along the English coast, comparing sediment and surface water to samples taken decades ago. They correlated these results to the production figures for synthetic fibres over the same period.

What they saw was mind-boggling.

The graphs showed exactly the same upward trend in the concentration of microplastics. The amount of fibrous synthetic material in the ocean had vastly increased since 1970 – apparently in tandem with the production of synthetic fibres. Although the researchers couldn’t yet conclude from these findings that one had directly caused the other, it was clear that something was wrong.

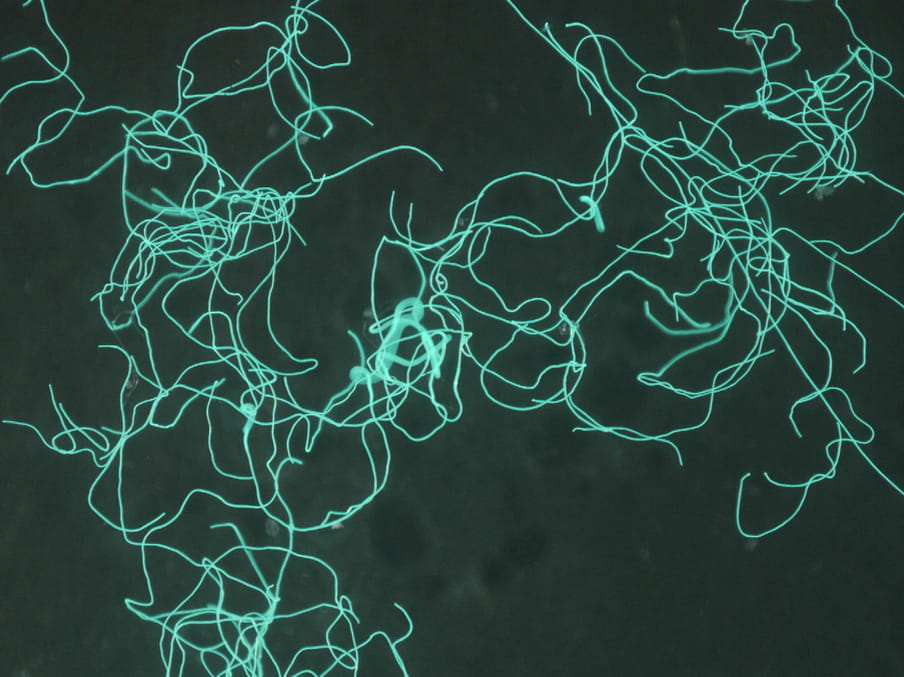

One of Thompson’s students, Mark Anthony Browne, decided to find out exactly where those microfibres in coastal areas were coming from. He took sediment samples from the coastlines on six continents back to a laboratory, meticulously separated the grains of sand from the plastic particles, then analysed the plastics.

As many as 1,900 fibres came from a single synthetic garment

Browne found the tiny pieces of colourful synthetics everywhere. The vast majority of the fibres, 85%, consisted of materials used to make clothing such as acrylic, polyester and nylon. The coastal areas where many people lived revealed a higher concentration of fibres.

How did the synthetic particles get there?

Browne’s hypothesis was that they flow into the sea in sewage. To test his assumption, he bought a pile of polyester blankets, fleece jackets and shirts. For three months, he washed them in a variety of washing machines. Each time, he captured the wastewater and filtered it.

The results identified as many as 1,900 fibres from a single synthetic garment: fibres so small that they passed right through the washing machine filters.

Browne was the first researcher to establish a direct connection between washing clothes and microplastics polluting the environment. His study was published in 2011, triggering more research into the release of microfibres. In recent years, data has been piling up.

For example, in 2016, researchers showed that a synthetic fleece jacket releases about 1.7 grams of microfibres per wash. Carried out by the University of California in Santa Barbara and funded by the Patagonia outdoor brand, the study also found that older jackets release twice as much fibre as new ones.

Older jackets release twice as much fibre as new ones

Results from a three-year European study were published a year later. That study showed that for every 5kg wash load of synthetic clothing, between 600,000 and 17.7 million garment fibres are released into the environment. That’s between about 0.43 and 1.27 grams in weight.

Shortly after, a report from the Ellen MacArthur Foundation calculated that half a million tonnes of microfibres end up in oceans every year as a result of washing clothes. That’s equivalent to more than 50 billion plastic bottles. Every year.

The sick silkworm and the new fabric

The enormous increase in microfibres in our oceans has tracked increasing demand for synthetic materials, polyester in particular. Some numbers: 16% of the world’s plastic production is synthetic textiles, of which 60% are polyester. Polyester consumption surged from 5.3 million tonnes in 1980, to 30.9 million tonnes in 2007, to its current level of about 50 million tonnes per year.

How did synthetic clothing – and polyester in particular – attain such dominance within the industry so quickly?

Until the late 19th century, clothing was made exclusively from natural materials. It was not until 1884 that the first artificial – that is, partly man-made – textile fibre was invented by French chemist Hilaire de Chardonnet. His research was prompted by a crisis in the silk industry.

Around 1860, silk production was hit by a disease which afflicted silkworms. Chardonnet found a way to treat cellulose – obtained from natural materials such as wood pulp, bamboo or eucalyptus wood – using a number of chemical applications to produce an artificial silk. This fabric was known as rayon or viscose.

Chardonnet’s invention was the basis for the development of nylon, the first fully synthetic fibre. Around 1930, Wallace Carothers, a US American researcher working for DuPont, a chemical company, then came up with the idea for a polyester fibre.

Polyester is a polymer, commonly made from polyethylene terephthalate or PET, a plastic refined from crude oil used to make soft drink bottles. The plastic is melted, then poured through a spinneret (a kind of filter resembling a shower head) to form long fibres. Stretch these filaments into thin strings, weave them together, and you have polyester fabric.

Resilient, easy-to-maintain textile fibre

DuPont didn’t immediately bring the new material to market. It took time to develop to its full potential. Researchers at the UK multinational Imperial Chemical Industries came up with the first practical version of polyester in 1940. DuPont bought the rights in 1945. In 1953, the company started commercial production of polyester for textiles, also known as Dacron.

The synthetic textile was a big hit in the US in the 1950s, where practical and economical ideas were welcomed after the shortages of the second world war. More and more, people were doing their own laundry at home with a personal washing machine, rather than taking it out to a laundrette. Clothing that dried quickly and didn’t need to be ironed was a fantastic find. The new fabric was launched with the promise of being resilient, easy to maintain and resistant to moths, mildew and bacteria. “Washed any way, they stay wash and wear for life ... and give you more value for your money,” declared a DuPont advertisement in the 1960s.

By the 1970s, polyester was widely used throughout the clothing industry, and in particular in leisure suits: matching trousers and jackets in the same colour (often bright, sometimes loud) with the look of a tailored business suit but the comfort of a tracksuit.

Polyester was seen as cheap, ‘unhip’ and uncomfortably warm

The popularity didn’t last. By 1980, leisure suits were no longer in demand: the fit was poor, the finish terrible. Polyester was seen as cheap, ‘unhip’ – and uncomfortable because it was too warm to wear.

To rescue the fabric’s suffering reputation, manufacturers (including DuPont, Celanese and Eastman Kodak) launched a campaign to convince people that polyester was still a miracle fibre. They emphasised its low-maintenance features, rather than the low price. From 1984, they hired world-famous designers, including Oscar de La Renta and Calvin Klein, to make collections in polyester or polyester blends.

Their efforts paid off – a bit ...

How polyester packed our wardrobes

The gradual advance in polyester’s popularity can be attributed more to technological factors than to marketing. The fabric was adapted to be cooler (hence less sweaty), and refined to look and feel more like natural materials such as silk, linen, wool or cotton. “The best silk costs 105 dollars a meter, while polyester silk costs only 12 dollars a meter,” an enthusiastic fashion designer told the New York Times in 1983.

The prominence of polyester and other synthetic materials in fashion is linked inextricably to the rise of fast fashion. The rapid advance of retail chains like H&M, Zara and Primark – an index of shoppers’ changing patterns of consumption – was made possible in part by polyester.

While manufacturers and designers were quick to point out unique properties in synthetic materials (water-repellent, quick-drying, resilient), for consumers the main motivation was price. A sweater made from acrylic wool or a blend of cotton and polyester is much cheaper than the same garment in 100% wool or cotton. And who will notice the difference?

Without realising it, we gradually packed our clothing racks and cupboards with plastics. Also without realising, we were rinsing more and more plastic particles into the ocean.

Just because we can’t see those fibres without a microscope doesn’t mean we shouldn’t worry about them. Various laboratory studies paint a disturbing picture: from crabs ingesting microfibres that stunt their growth, to fish larvae exposed to high concentrations of plastic particles making them smaller, slower and more susceptible to predators. Whether these effects, observed in laboratories, also occur in the natural environment has not yet been proved.

Nor is the potential harm from microfibres confined to the animal kingdom; humans are ingesting them too.

Plastic in the food chain

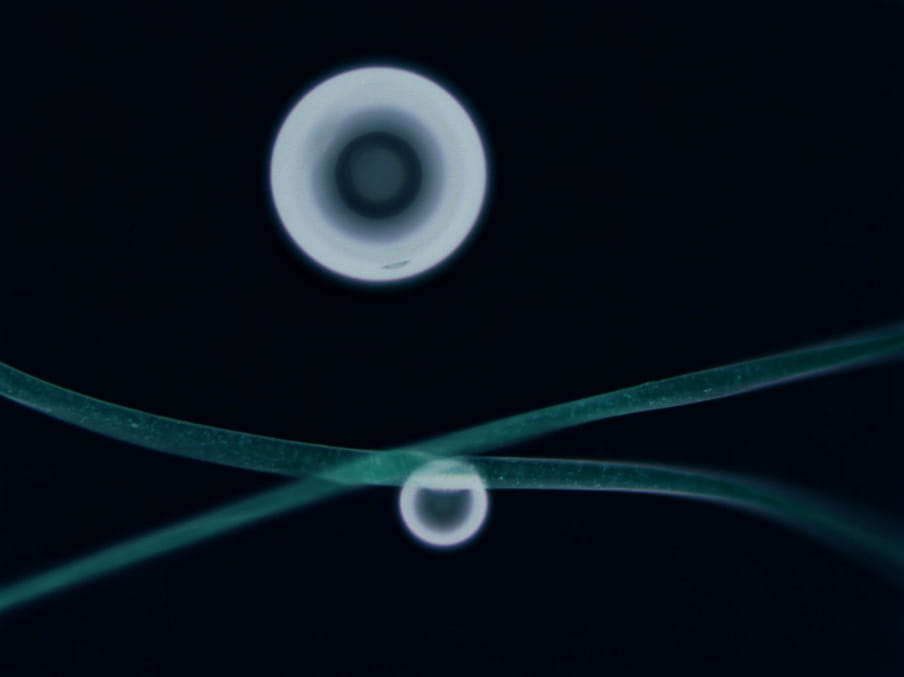

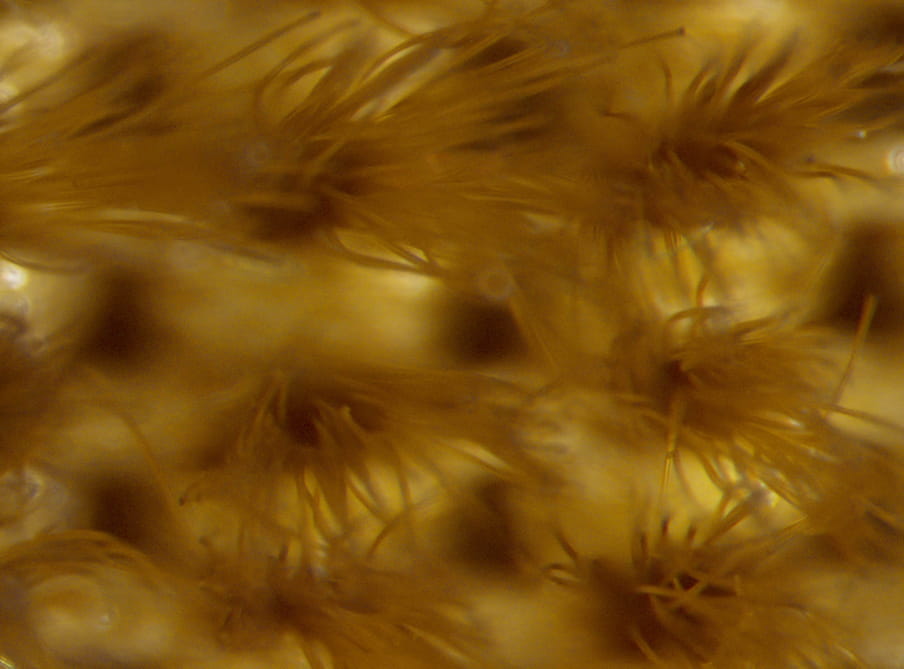

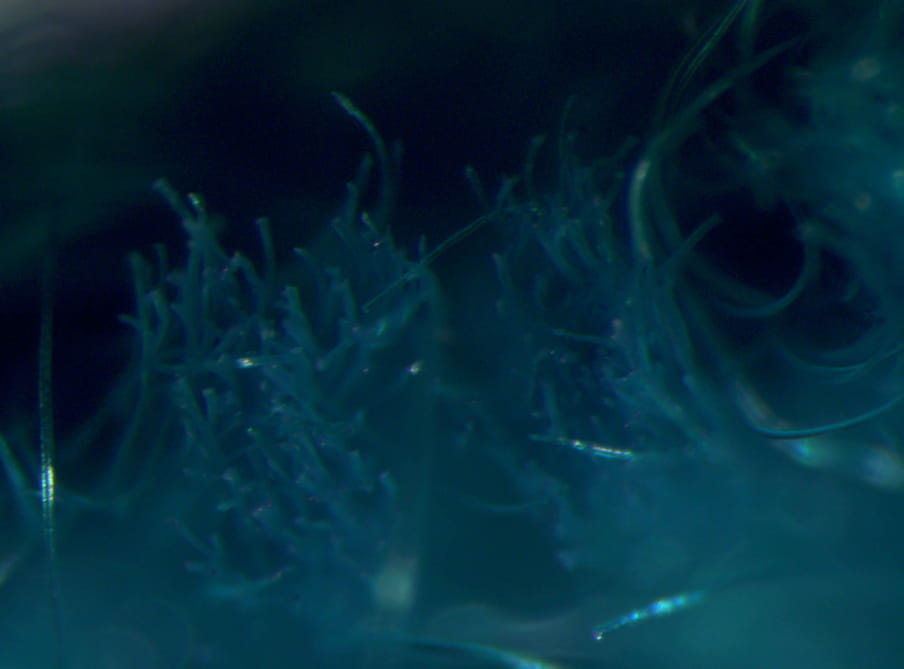

In 2017, researcher Richard Kirby shared a video showing a blue fibre inside the body of a plankton. For the first time, these images made plainly visible to everyone how plastic enters our food chain.

Most people, Kirby tells me by email, have seen pictures of bigger pieces of plastic that end up in nature: photos of birds, fish or marine mammals entangled in plastic, or which died after eating it. But the damage caused by tiny plastic fibres is still invisible: “I wanted to show the world that plastic pollution affects the entire food chain, starting with plankton and microplastics.”

Almost every sample of coastal plankton which Kirby has taken recently contained microplastic pollution. He often observes plankton eating microfibres.

How many of those microplastics in the sea come from clothing? A IUCN report published in 2017 found that between 15% and 31% of all microplastics in the ocean can be traced to their primary sources. A significant percentage of those, 34.8%, reach the sea as a result of washing synthetic textiles. The second-largest source are particles shed by car tyres while driving, accounting for 28.3%, followed by plastic particles from paint.

The fact that synthetic microfibres are a major pollutant in the oceans is not the only reason for growing concern among scientists and environmental experts. These particles could also be toxic. Many garments are treated with chemicals that affect humans and the environment: synthetic dyes can cause skin rashes; waterproofing treatments can damage the immune system; antimicrobials such as Triclosan cause harm to the environment.

Research into possible effects of chemical substances adhering to microfibres is cause for alarm. Fish subjected to prolonged exposure to toxins in microplastic pellets will develop liver damage and other pathological ailments. Richard Kirby is worried: “Plankton are the basic level of the marine food chain. All the plastics they eat are passed on.”

Plastic doesn’t decompose.

The particles are all around us

As if that wasn’t bad enough: the fibres from synthetic clothing don’t just enter the environment (and eventually our bodies) when we wash our clothes. These particles are all around us, in the air we breathe.

Wave a fleece jacket or blanket in bright sunlight, and you’ll see hundreds of tiny dust particles floating in the air. Between the motes of dust are the microfibres – invisible to the naked eye – and easily inhaled, or imbibed, via your nose or mouth.

In March this year, a team of French and English scientists published an article in Elsevier Science, "Microplastics In Air: Are We Breathing It In?" Discussing the presence of microfibres in the air, indoors and out, the researchers note that both natural and synthetic textile fibres may be harmful to human health. These particles may penetrate deep into the lungs and stay there.

Although most inhaled particles are expelled by the body, those lodged in the lungs can cause inflammation. The researchers conclude that “further interdisciplinary research is urgently needed” to assess the health effects of all these particles.

Dick Vethaak, professor of water quality and health at Vrije Universiteit Amsterdam and affiliated with Deltares research institute, concurs. “We still know far too little about the impact on humans. We know that these plastic particles end up in our intestines and lungs, but how much exposure is there, and can [they] also be absorbed into our bodies and cause harmful health effects? We have no idea.”

Environmental toxicologists have only recently begun to talk to the medical world about this. For example, Vethaak is working with a pulmonary specialist and a paediatrician to explore the potential harm from inhaling plastic particles and fibres. With his colleagues at VU University, he will soon investigate how many microplastics find their way into the human body, and where they are located. He explains: “It’s mainly about the smallest plastic particles, like tiny fibre fragments and fibrils, which can pass through biological membranes and enter cells. We want to analyse the extent to which the particles are present in the brain, the amniotic fluid, the placenta, but also for example in breast milk.”

What is the industry doing?

One of the biggest problems I have encountered in the whole story about microfibres is that we have no benchmark. We are continuously exposed to synthetic fibres from our clothing. They are in the water we drink, the air we breathe, the animals we eat. But how harmful are these tiny textile fibres to our health?

No one knows.

Every researcher relies on their own testing and methods. Type of washing machine, washing programme, detergent, size of the laundry load in the machine, the method by which microfibres are counted: none of this is standardised.

Without a common frame of reference, it’s almost impossible to determine accurately how many microfibres end up in the environment – from washing clothes or by other means. Until the extent to which we’re exposed is clear, it’s impossible to say how much harm has been – and is – caused by synthetic microfibres.

The lack of clear benchmarks is an excuse for industry to avoid taking action, says Maria Westerbos from Plastic Soup Foundation, a non-profit organisation which has worked on this issue since 2014. “The clothing industry says: we don’t know; we have no idea how to measure the microfibres coming from our clothes.” And so almost nothing is being done.

When Mark Anthony Browne asked clothing companies including Patagonia and Nike (both consume large quantities of synthetic materials) to collaborate on further research following his 2011 study, they refused his offer.

Patagonia, a brand known for its strong environmental ethics, argued that it was necessary, first, to compile more evidence for the potential harm caused by specific products. “I don’t know how much effort we want to spend looking for the solution before we know where the problem is,” Todd Copeland, strategic environmental responsibility manager at Patagonia, told the Guardian in 2014.

Asked if Patagonia has taken further measures, PR manager Louise Brierley-Ingham shares a list of studies that the brand has funded or co-funded. They now “have a better idea of how much microplastic comes off clothes and what factors affect that”. Work on a remedy has not been envisaged: “First we need to gain more insight into the scope and exact cause of the problem.”

Swedish outdoor brand Fjällräven offered a similar response. Corporate social responsibility manager Christiane Dolva emails that: “We need to look for products that limit the release of plastic microfibres.” More knowledge is needed before that can happen, writes Dolva: “We want to be able to make decisions based on facts.”

These brands are the frontrunners. Take a good look at the sustainability reports released by the world’s largest clothing companies, and most have barely looked at the problem. At most, you’ll see a small text box commenting on microfibres in the margin. It simply isn’t considered a high priority – not yet.

Pumping plastic around actually leads to more pollution

Ironically, fashion brands contributing most to plastic pollution often claim they are actually helping to solve it.

Take G-Star Raw, the Dutch brand which, in 2014, launched Raw For The Oceans, a grand campaign with a new clothing collection made partly with fibres derived from plastic bottles washed ashore from the ocean.

Rap star Pharrell Williams, who helped to design the garments, made a vivid video clip: the oceans are filled with plastic waste, he warned, but G-Star Raw and Bionic Yarn (the fibre producer, and supplier) are taking responsibility.

Then there’s Adidas. “This is how we’re transforming the problem into a solution,” the sports brand writes on its website. Adidas claims it’s taking steps to ensure that plastic waste no longer ends up in the oceans. Instead, it’s turning waste material into ingredients for sportswear: “This is how we’re transforming the problem into a solution.”

To date, Patagonia (which first sold clothing made from recycled PET bottles in 1993) has recycled some 86 million plastic bottles, mostly to make fleece jackets. H&M recycled 100 million plastic bottles in 2017. In 2018, Nike’s chief operating officer, Eric Sprunk, proudly announced the company had become one of the biggest buyers of recycled plastic: “Since 2012, we have diverted more than 5 billion plastic bottles from landfills and recycled them into new fabrics.”

Such claims sound fantastic. But synthetic textiles made from recycled plastic thread actually pose a higher risk than new materials because they tend to produce more microfibres. Recycled fabrics are less robust than textiles made from new plastic fibres.

“Are we doing the right thing by using recycled polyester that might shed more? It has added a whole other big question mark,” acknowledges Katy Stevens, a sustainability project manager with the European Outdoor Group (EOG), an industry organisation that represents the interests of the sector.

We’ll just capture the fibres, right?

Not everyone is ready to wait until a standard measurement method is developed, or until the industry finally takes action.

Alexander Nolte and Oliver Spies are surf buddies and co-owners of Langbrett, a German retailer with four shops for surf gear and outdoor clothing (mostly made of synthetic materials). They’ve come up with their own solution: the Guppy Bag, a plastic-based laundry bag for your clothes, to prevent microfibres from being released into the water during washing. Nolte and Skewer claim the bag captures 80% to 90% of the fibres.

The Guppy Bag is made of polyamide (nylon) – plastic, in other words. Isn’t it strange to use plastic to address the plastic problem? “It might sound crazy,” Nolte responds over the phone, “but this material turned out to be perfect; no fibres pass through the fabric, but soap and water can get into the bag without any problems.” Also important: the bag remains functional and intact even after hundreds of washes, according to Nolte and Spies.

Another gadget designed and released to catch microfibres is the Cora Ball, made of recycled plastic. The ball consists of small rings to collect the clothing fibres during washing. Megan Bender, from the US-based company, claims the ball can capture a third of the particles released during washing.

How do you get those microfibres out of the laundry bag or ball? I imagine them flying around the bathroom

That’s a nice idea. But do they actually work? I asked the scientists.

Opinions differ. Dick Vethaak, professor of water quality and health, wondered what happens when you try to remove the microfibres from the Guppy Bag or Cora Ball. “I can imagine those fibres flying around the bathroom.”

Ecologist Mark Anthony Browne was not convinced, either. “Where is the peer-reviewed scientific evidence showing that these types of things work? And that they don’t actually lead to more emissions or impacts on people, wildlife, clothing, the water supply, etc?”

Critical voices suspect these gadgets are decoys, a means for companies to avoid taking responsibility for the larger issues. Consumers can fork over €30 for a laundry bag that has not even been proven effective in order to solve a problem for which the industry is responsible.

Other experiments are taking place that may bring remedies: special washing machine filters, for example, or a coating for the fabrics to prevent microfibres from coming loose.

Shouldn’t we just stop using those fibres?

Isn’t the obvious solution to stop using synthetic fibres in clothing altogether?

“That’s not going to happen,” Maria Westerbos from the Plastic Soup Foundation tells me. “Because what’s the alternative? Cultivating cotton requires an incredible amount of water and pesticides and chemicals.”

She concurs with scientists who advocate development of new synthetic materials that release minimal quantities of fibre during washing. Despite mounting evidence, however, the clothing industry feels little urgency to take action. It’s easier to continue on their current course — for as long as the harm has not been established indisputably.

California is considering a bill for a warning label in clothing made from synthetic fabrics

A more immediate option is mandatory warning labels on clothing made from synthetic materials. In California, that idea is under consideration: a state bill could require a label on all garments containing 50% polyester or more to warn of the risk from microfibres released during washing.

The label could recommend hand-washing the garment – it’s likely that the speed of a washing machine’s spin cycle causes more fibres to come loose. While it’s unclear whether that will really make a difference, Browne is an advocate for labels: “In any case, it makes people more aware of the problem.”

That awareness is sorely needed and long overdue. Forecasts indicate the clothing industry’s demand for polyester fabrics will continue to grow – so microfibres in nature are set to just keep increasing.

The consequences for people and planet are not yet clear. But it seems to be clear that intervening now can save a lot of trouble in the future.

This article first appeared on De Correspondent. It was translated from the Dutch by Joy Phillips.

Dig deeper

Fashion unravelled: why you get holes in your T-shirts faster (even when you pay more)

A shirt that shrinks two sizes after a single wash, jeans that rip too quickly or bikini bottoms that are baggy after just one holiday. The quality of clothes is declining. Even high-end brands sometimes seem like they don’t last much more than one season. The reason? Fashion has to be fast.

Fashion unravelled: why you get holes in your T-shirts faster (even when you pay more)

A shirt that shrinks two sizes after a single wash, jeans that rip too quickly or bikini bottoms that are baggy after just one holiday. The quality of clothes is declining. Even high-end brands sometimes seem like they don’t last much more than one season. The reason? Fashion has to be fast.